What Are Excavator Pins Made Of?

Excavator pins are subjected to tremendous force, making durability and wear resistance essential qualities for this component. Typically, high-grade materials such as alloy steel, carbon steel, and chromium are used to manufacture excavator pins, as these metals offer the strength and resilience necessary for withstanding the mechanical stresses experienced in heavy-duty operations.

Alloy Steel Alloy steel is a preferred material for excavator pins because of its impressive strength and toughness. Often enriched with elements like manganese, nickel, or chromium, alloy steel provides an excellent balance of hardness and flexibility. This balance is critical for excavator pins, as they need to resist bending under heavy loads while also enduring constant wear and tear. Jinxin’s excavator pins, including the E345 excavator tooth pin, often incorporate alloy steel, which allows the pins to last longer under high-stress conditions, making them a reliable choice for excavator attachments.

Carbon Steel Carbon steel is another common material used in excavator pins. Known for its robustness and durability, carbon steel is especially suitable for pins that need to withstand repetitive forces. High-carbon steel, which has higher carbon content, is preferred for its increased hardness. While not as flexible as alloy steel, carbon steel excels in providing rigidity to excavator pins, ensuring they remain steady even under intense pressure. Jinxin uses quality carbon steel in its manufacturing process, creating excavator pins that meet stringent durability standards.

Chromium Plating and Hardening For added durability, Jinxin employs chromium plating or hardening techniques on their excavator pins. Chromium, a highly corrosion-resistant metal, enhances the pin’s lifespan by protecting it against rust and surface wear. The hardening process not only increases the pin’s surface strength but also prevents abrasions, making it especially useful in challenging environments. For Jinxin’s E345 excavator tooth pins, the hardening and plating processes ensure that the pins retain their structural integrity over time, even with continuous use in harsh conditions.

The Role of E345 Excavator Tooth Pin

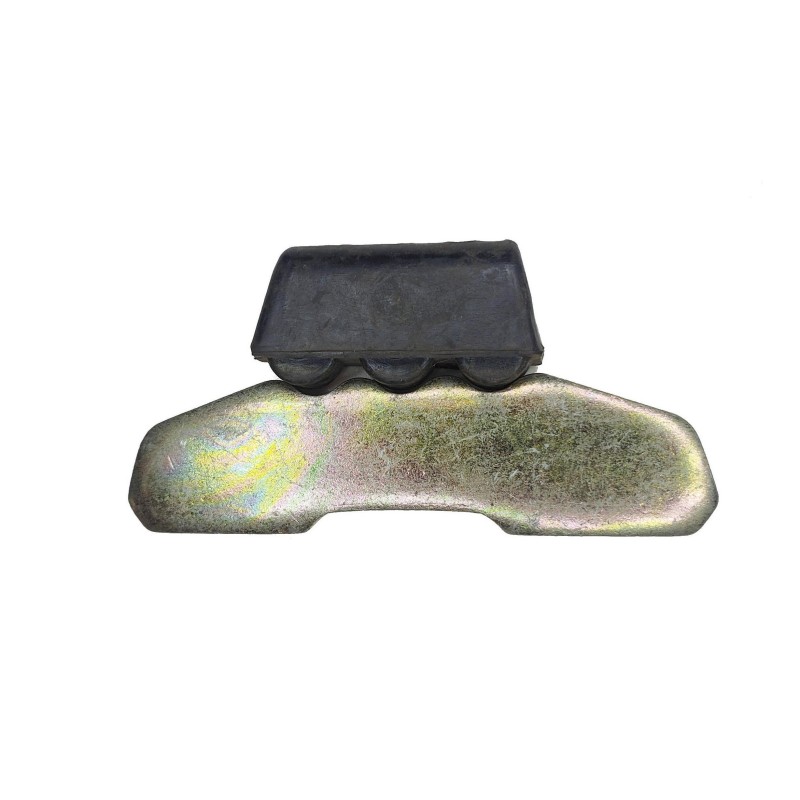

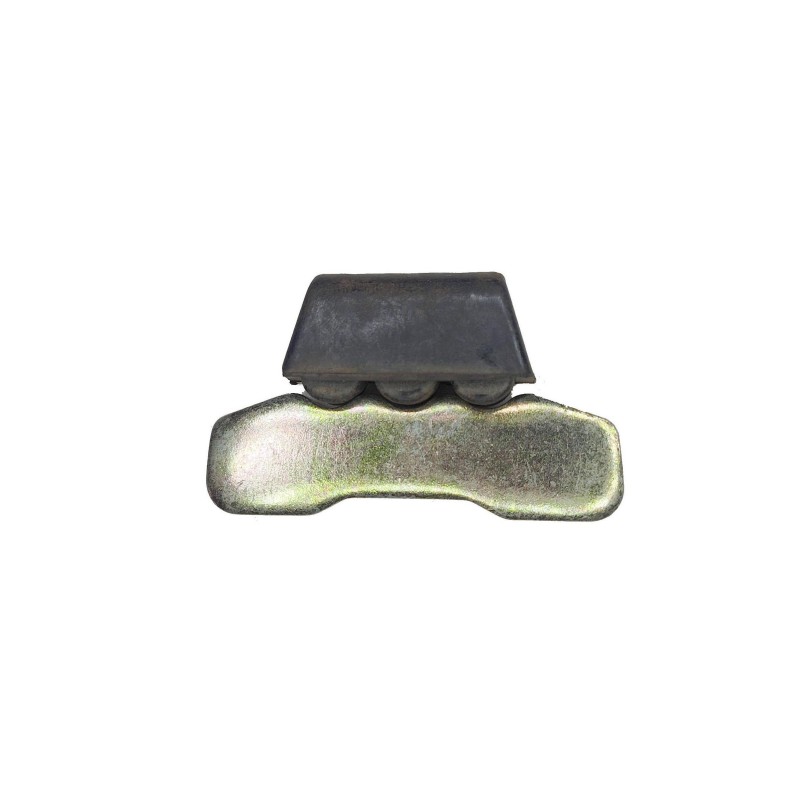

The E345 excavator tooth pin is a specific type of pin designed to secure bucket teeth on excavators. The bucket teeth are a key component that directly interacts with tough materials like soil, rocks, and gravel. Therefore, a durable and robust tooth pin is necessary to keep these teeth in place and prevent any operational interruptions. Jinxin’s E345 excavator tooth pin is engineered to offer exceptional holding power, making it an ideal choice for excavator operators who demand reliability and strength in their equipment.

Features of the E345 Excavator Tooth Pin by Jinxin:

Enhanced Durability: Made from premium alloy or carbon steel, the E345 excavator tooth pin by Jinxin is designed to last. Its durability helps prevent frequent replacements, saving time and costs on maintenance.

Precision Fit: Jinxin’s manufacturing process ensures that each E345 excavator tooth pin is crafted with precision, allowing for a tight fit that holds bucket teeth securely in place. This fit minimizes the risk of pin loosening, which can be a common issue in excavators that work in high-vibration environments.

Anti-Corrosion Properties: With additional treatments such as chromium plating, Jinxin’s E345 tooth pins are highly resistant to corrosion. This characteristic is especially important for excavators used in wet or humid environments, as it extends the pin’s life and maintains its performance.

Cost-Effective Solution: By choosing Jinxin’s high-quality tooth pins, operators and equipment managers can avoid frequent replacements, ultimately reducing costs and increasing operational efficiency. This cost-effectiveness makes Jinxin’s E345 excavator tooth pins a popular choice among contractors and construction companies.

Jinxin: Leading Manufacturer of Excavator Pins

Jinxin has established itself as a reliable brand in the excavator parts market, focusing on quality and innovation. With years of experience, Jinxin not only meets but often exceeds industry standards in excavator pin production. Here’s why Jinxin’s products are trusted by clients worldwide:

Advanced Manufacturing Techniques: Jinxin employs cutting-edge technology in the production of excavator pins. Their processes involve rigorous quality control and precision engineering, ensuring that each pin meets the highest standards.

Wide Range of Products: Jinxin offers a diverse selection of excavator pins, including the E345 excavator tooth pin, available in different sizes and specifications to suit various excavator models. This range allows clients to find the exact parts they need, whether they require specific dimensions or customized options.

Customer-Centric Approach: Jinxin’s customer service team is known for its responsiveness and commitment to client satisfaction. They work closely with customers to understand their needs and provide tailored solutions, whether for bulk orders or specialized requests.

Competitive Pricing: Jinxin’s products are offered at competitive prices, making them an attractive choice for businesses seeking cost-effective solutions without compromising on quality. The brand’s focus on affordability, coupled with durability, ensures clients get the best value for their investment.

Conclusion: Choose Jinxin for Quality Excavator Pins

Excavator pins, especially tooth pins like the E345, are indispensable in maintaining the functionality and efficiency of heavy-duty machinery. With high-quality materials such as alloy steel and carbon steel, and advanced anti-corrosion treatments, Jinxin’s excavator pins offer the durability and reliability needed for demanding applications. Jinxin’s expertise in the field and commitment to quality make it a leading choice for excavator operators worldwide.

Whether you’re looking for a standard excavator pin or a specific model like the E345 excavator tooth pin, Jinxin’s comprehensive range and customer-oriented approach ensure you’ll find a solution that meets your needs. With Jinxin, clients gain not only a product but also a reliable partner in keeping their equipment operating smoothly and efficiently.

No. 550, Xiacuo, Sihuang Village, Xiamei Town, Nan'an City, Quanzhou City, Fujian Province, China

No. 550, Xiacuo, Sihuang Village, Xiamei Town, Nan'an City, Quanzhou City, Fujian Province, China

Contact

Contact